5 APRIL 2010Report duty at Jabatan Kerja Raya (JKR), Mechanical Engineering Branch, Mid Valley and met Mr. Adam Bin Sidek (

Jurutera Mekanikal Kanan) and Mr. Mohd Yusoff Bin Ahmad (

Jurutera Mekanikal Kanan).

6 APRIL 2010Learn on JKR organization's profile and chart.

JKRORGANIZATION PROFILE Jabatan Kerja Raya (JKR) Malaysia was constituted since 1872 and function as a technical agency to Malaysia Government. JKR with role implement projects infrastructure development and maintenance to various ministry, department, statutory body and state government such as road, building, airport, port and jetty.

ORGANISATIONAL STRUCTUREJKR Malaysia helmed by a Public Works Director-General (

Ketua Pengarah Kerja Raya) aided by 3 Deputy Director-General Public Works (

Timbalan Ketua Pengarah Kerja Raya).Jabatan Kerja Raya Malaysia administration covering whole of Malaysia except Sarawak and Sabah. For administrative purposes, JKR Malaysia divided into two namely in Headquarters level and State.

HEADQUARTER JKR MALAYSIA In Headquarters, department is managed following three major business sector with 14 branches except one branch do not stay under business sector. Further information on business sector and branches are such as :

• Corporate Management Branch

• Infrastructure Sector

Road Branch

Airbase And Maritime Branch

Water Supply Branch

Slope Engineering Branch

• Building Sector

General Building Work Branch

Health Work Branch

Education Work Branch

• Expert Sector

Architect Branch

Expert Branch And Kejureuteraan Public

Mechanical Engineering Branch

Electric Engineering Branch

Contract And Material Measure Branch

Environment Branch

Headquarters JKR Malaysia responsible to draw and design development projects, monitor projects implementation, and policy preparation, guideline and technical advice to JKR State, JKR Federal Territory, JBA State and JKR Special Unit.

JKR STATEJKR State helmed by a Director (

Pengarah) and responsible to draw, implement and maintain state development projects such as road and government building, beside water supply for Kedah and Perlis. In other states, water supply services whether was corporatised or privatized.JKR State directly responsible to State Government for all state project and favoured with advice by Headquarter JKR Malaysia. At the same time, JKR State also responsible continue to KPKR for federal projects in each state (except JKR Sabah and Sarawak).

JKR FEDERAL TERRITORY There Is 3 JKR Federal Territory:

• JKR Kuala Lumpur Federal Territory

• JKR Labuan Federal Territory

• JKR Federal Territory Of Putrajaya

Every JKR Federal Territory helmed by a Director (

Pengarah) directly responsible to KPKR. JKR Federal Territory responsible to implement projects development and maintain government buildings certain in Kuala Lumpur, Labuan and Putrajaya. Other than that, JKR Federal Territory also maintain water supply and road in Labuan.

JKR SPECIAL UNITJKR Malaysia having JKR SPECIAL UNIT to implement, coordinate, and monitor federal development projects, Provincial Authorities or special project. Units helmed by a Director (

Pengarah directly responsible to KPKR. JKR SPECIAL UNIT among others are made up JKR Pembangunan Persukutuan for Kelantan and Sabah, JKR Pembangunan Wilayah KESEDAR, and JKR Projek Khas Gerbang South.

JKR DISTRICT / COUNTRY AND WATER SUPPLY DEPARTMENTEvery office presided by a District Engineer or Jurutera Jajahan (for Kelantan state) directly responsible to JKR Director State (

Pengarah JKR Negeri) or JBA respective State to carry and organize Federation's projects and State.

BRANCH OBJECTIVE MECHANICAL ENGINEERING BRANCH1. Complete mechanical system design work fulfilling standard,

quality, time and cost that is fixed.

2. Hand over mechanical system project fulfil, quality, time and

which cost fixed.

3. Carrying out work mechanical system maintenance, vehicle, plant

quarry road construction and plant government's asset fulfil quality,

time and cost that is fixed.

4. Manage those assets are made up mechanical system indoor,

vehicle, road and plant construction plant quarry belonging to JKR who can

cater to department current need.

5. Provide technical negotiation service with regard to field

mechanical engineering to government agency and statutory body with

right and quick.

CKM MAIN FUNCTION (MECHANICAL ENGINEERING BRANCHMechanical Engineering Consultation ServiceImplement mechanical design engineering works in national development projects executed by Public Works Department whether by own Sektor Bisnes or CKM such as planning, service design and supervision mechanical in government building until project delivery, including maintenance work after it. Mechanical services in government building premises were as follows :

• Air Conditioner And Air Changing System

• Hot Water System

• Fire Preventive System

• Equipment System Dental Chair

• Water And Sanitary Supply System Internal

• Pneumatic Tube System

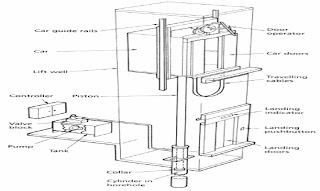

• Lift System

• Automation's System Building

• Crane System

• Compression System Air

• Booster Pump System

• Fume Chamber System

• Medical Gas System

• Pool System Hydrotherapy

• Boiler And Steam System

• Burner System

• Penstril System

• Equipment System Laundry

• Kitchen Equipment System And LPG

Project Management Services For Mechanical Engineering ProjectImplement mechanical service project management service for national development projects implemented continue by own CKM. Mechanical services which included is as mentioned above.

Implement Expertise And Research ActivityApply energy efficiency field in generating mechanical design in a building and further recommend energy saving move in mechanical systems operations.

Recommend improvement move in sound control application & vibration in something a mechanical service system building.

Determine check & balance in something mechanical equipment installation through testing, commissioning and forensic aims to prevent equipment from continue to experience damage and further identify damage cause and propose recovery action plan to avoid problem same repeat.

Implement internal environmental quality (Indoor Quality Water & Indoor Environment Quality) IAQ & IEQ aimed to ensure air supply to resident places according to standard and specification not to contributed to health problem due to sick building syndrome(SBS).

Drafting policy, policy, study and encourage innovation and research field and development on specific expertise activity mechanical engineering field.

Provide standard, supervision, testing, mechanical service commissioning, develop specification, garispanduan design, technical directive in mechanical engineering field.

Provide information centring on for all mechanical activity including information mechanical projects, cost of around and real mechanical works, mechanical contractor performance and so on.

Create mechanical experts in mechanical service field such as System Expert Air Conditioning, System Expert Fire Preventive, Energy Efficiency Expert, Vibration Expert & Sound and so on.

Increase role and expertise in building maintenance business including Condition Monitoring application on mechanical system equipment.

UNIT LIST EXPERTISE DEVELOPMENT DIVISION

• Expert Unit Internal Air Conditioning And Air Quality

• Expert Unit Fire Preventive And Special Risk

• Expert Unit Material Transport And Operand

• Expert Unit Medical Equipment

• Engineering Specialist Unit Fluid

• Expert Unit Energy Efficiency & Renewable Energy

o Retrofitting

o New Project

• Expert Unit Sound Control & Vibration

• Testing Unit, Commissioning & Forensic

• Cost And Supervision Control Unit Project

MANAGEMENT DIVISION AND OPERATION

• Plant Development Unit & Quarry

• Human Resource Management Unit

o Organizational Development (UPO)

o Finance

o Administration

• Junctor & Project Monitoring In States

DESIGN DEVELOPMENT DIVISION

• Design Unit Air Port & Maritime

• Design Unit Security

• General Building Design Unit 1

• General Building Design Unit 2

• General Building Design Unit 3

• Design Unit Health

• Design Unit Education

• Design Unit Tertiary Education

PROPERTY SERVICES DIVISION (Workshop Federal)

• Pelupusan unit & count extinct

• Inspection Unit, Testing & Standard Compliance

• VVIP Transport's Service Unit

• Finance Administrative Unit & Store

Contract Unit & Material Measure

ORGANIZATION CHART MECHANICAL ENGINEERING BRANCH